Page 26 - Dillon_2024 Catalog_501427.indd

P. 26

FORCE MEASUREMENT EQUIPMENT

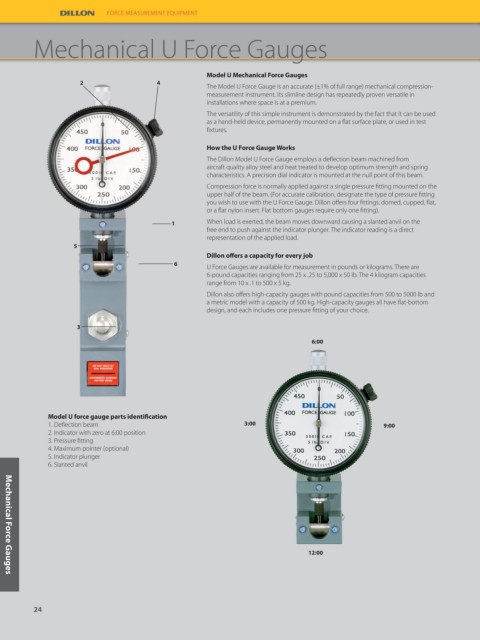

Mechanical U Force Gauges

Model U Mechanical Force Gauges

2 4

The Model U Force Gauge is an accurate (±1% of full range) mechanical compression-

measurement instrument. Its slimline design has repeatedly proven versatile in

installations where space is at a premium.

The versatility of this simple instrument is demonstrated by the fact that it can be used

as a hand-held device, permanently mounted on a flat surface plate, or used in test

fixtures.

How the U Force Gauge Works

The Dillon Model U Force Gauge employs a deflection beam machined from

aircraft quality alloy steel and heat treated to develop optimum strength and spring

characteristics. A precision dial indicator is mounted at the null point of this beam.

Compression force is normally applied against a single pressure fitting mounted on the

upper half of the beam. (For accurate calibration, designate the type of pressure fitting

you wish to use with the U Force Gauge. Dillon offers four fittings: domed, cupped, flat,

or a flat nylon insert. Flat bottom gauges require only one fitting).

1 When load is exerted, the beam moves downward causing a slanted anvil on the

free end to push against the indicator plunger. The indicator reading is a direct

representation of the applied load.

5

Dillon offers a capacity for every job

6 U Force Gauges are available for measurement in pounds or kilograms. There are

6-pound capacities ranging from 25 x .25 to 5,000 x 50 lb. The 4 kilogram capacities

range from 10 x .1 to 500 x 5 kg.

Dillon also offers high-capacity gauges with pound capacities from 500 to 5000 lb and

a metric model with a capacity of 500 kg. High-capacity gauges all have flat-bottom

design, and each includes one pressure fitting of your choice.

3

6:00

Model U force gauge parts identification

1. Deflection beam 3:00 9:00

2. Indicator with zero at 6:00 position

3. Pressure fitting

4. Maximum pointer (optional)

5. Indicator plunger

6. Slanted anvil

12:00

Mechanical Force Gauges

24