Page 22 - Dillon_2024 Catalog_501427.indd

P. 22

FORCE MEASUREMENT EQUIPMENT

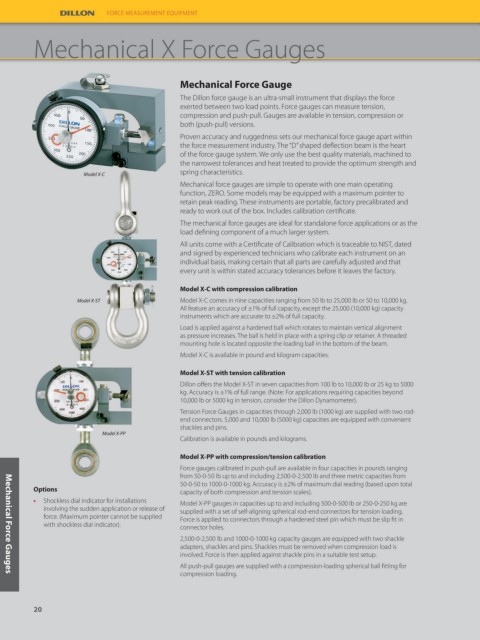

Mechanical X Force Gauges

Mechanical Force Gauge

The Dillon force gauge is an ultra-small instrument that displays the force

exerted between two load points. Force gauges can measure tension,

compression and push-pull. Gauges are available in tension, compression or

both (push-pull) versions.

Proven accuracy and ruggedness sets our mechanical force gauge apart within

the force measurement industry. The “D” shaped deflection beam is the heart

of the force gauge system. We only use the best quality materials, machined to

the narrowest tolerances and heat treated to provide the optimum strength and

spring characteristics.

Model X-C

Mechanical force gauges are simple to operate with one main operating

function, ZERO. Some models may be equipped with a maximum pointer to

retain peak reading. These instruments are portable, factory precalibrated and

ready to work out of the box. Includes calibration certificate.

The mechanical force gauges are ideal for standalone force applications or as the

load defining component of a much larger system.

All units come with a Certificate of Calibration which is traceable to NIST, dated

and signed by experienced technicians who calibrate each instrument on an

individual basis, making certain that all parts are carefully adjusted and that

every unit is within stated accuracy tolerances before it leaves the factory.

Model X-C with compression calibration

Model X-ST Model X-C comes in nine capacities ranging from 50 lb to 25,000 lb or 50 to 10,000 kg.

All feature an accuracy of ±1% of full capacity, except the 25,000 (10,000 kg) capacity

instruments which are accurate to ±2% of full capacity.

Load is applied against a hardened ball which rotates to maintain vertical alignment

as pressure increases. The ball is held in place with a spring clip or retainer. A threaded

mounting hole is located opposite the loading ball in the bottom of the beam.

Model X-C is available in pound and kilogram capacities.

Model X-ST with tension calibration

Dillon offers the Model X-ST in seven capacities from 100 lb to 10,000 lb or 25 kg to 5000

kg. Accuracy is ±1% of full range. (Note: For applications requiring capacities beyond

10,000 lb or 5000 kg in tension, consider the Dillon Dynamometer).

Tension Force Gauges in capacities through 2,000 lb (1000 kg) are supplied with two rod-

end connectors. 5,000 and 10,000 lb (5000 kg) capacities are equipped with convenient

shackles and pins.

Model X-PP

Calibration is available in pounds and kilograms.

Model X-PP with compression/tension calibration

Force gauges calibrated in push-pull are available in four capacities in pounds ranging

from 50-0-50 lb up to and including 2,500-0-2,500 lb and three metric capacities from

50-0-50 to 1000-0-1000 kg. Accuracy is ±2% of maximum dial reading (based upon total

Options capacity of both compression and tension scales).

• Shockless dial indicator for installations Model X-PP gauges in capacities up to and including 500-0-500 lb or 250-0-250 kg are

involving the sudden application or release of supplied with a set of self-aligning spherical rod-end connectors for tension loading.

force. (Maximum pointer cannot be supplied Force is applied to connectors through a hardened steel pin which must be slip fit in

with shockless dial indicator). connector holes.

2,500-0-2,500 lb and 1000-0-1000 kg capacity gauges are equipped with two shackle

adapters, shackles and pins. Shackles must be removed when compression load is

involved. Force is then applied against shackle pins in a suitable test setup.

All push-pull gauges are supplied with a compression-loading spherical ball fitting for

compression loading.

Mechanical Force Gauges

20